Product and Technical Information

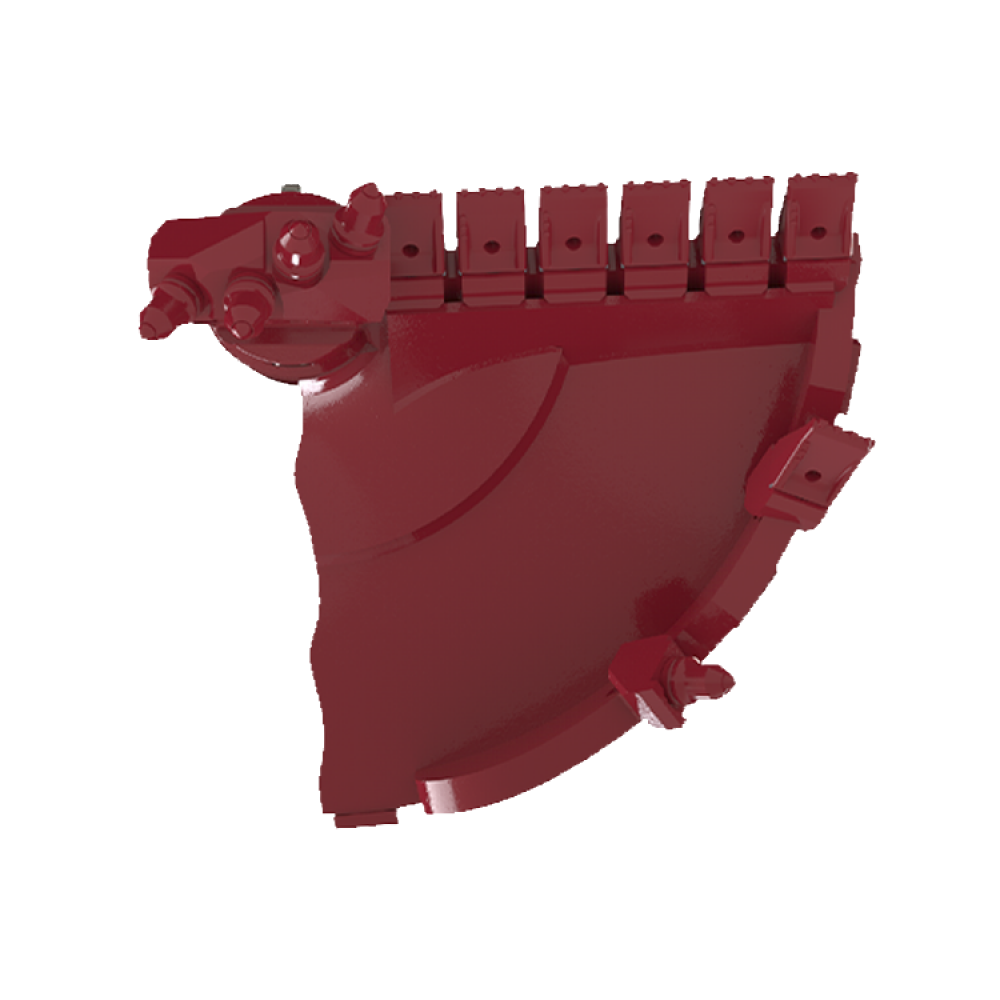

Key features of the 60″ Cut Core Barrel include:

– Kelly boxes that are tailored to the customer’s specifications, ensuring a perfect fit with their drilling equipment.

– Standard 1-inch thick gussets that provide additional strength and support to the core barrel structure, enhancing its durability during drilling operations.

– Barrel thickness options of up to 2 inches, offering robust construction capable of withstanding demanding drilling tasks.

– Two undersize options for the cutting teeth to allow for optimal cutting performance: a 2-inch undersize for .990 teeth and a 3-inch undersize for 38mm teeth.

– The height of the core barrel is determined by the customer, allowing for a customized solution based on the specific requirements of the drilling project.

– Various layout pattern options for the placement of the teeth, including 3 tooth, 5 tooth, and 7 tooth configurations, which can be selected to match the drilling conditions and desired cutting efficiency.

For the core barrel parts, customers have a choice between .990 Rock Wear Parts and 38mm Rock Wear Parts. The .990 options include:

– .990 Standard (30122) for general rock drilling applications.

– .990 Dragon’s Tooth® (30145) for enhanced cutting action and wear resistance.

– .990 Dragon Holder (32049) to securely hold the .990 teeth in place.

The 38mm Rock Wear Parts are designed for heavy-duty rock drilling and include:

– B47K19LK80-H (30182), which is a robust tooth option for challenging rock conditions.

– 38mm Dragon’s Tooth® (30188) for aggressive cutting and extended service life.

– 38mm Round Dragon Holder (32110) to accommodate the 38mm teeth.

The 60″ Cut Core Barrel is engineered to provide reliable and efficient drilling performance, with a focus on customization to meet the diverse needs of drilling projects in various ground conditions.

For outstanding service and expert advice, call us today at (877) 852-0012.

© 2024 AKSELA, LLC.